CNC Plastic Part Machining

Advanced Industrial’s Capabilities

Plastic machining takes skill and precision to ensure quality production. As a Tier 1 plastic machining services provider, distributor, and plastics fabricator, Advanced Industrial specializes in supplying tight tolerance, high-performance plastic machined parts. Our inventory includes an extensive stock of plastic blanks of premade bars, plastics, rods, tubes, and sheets.

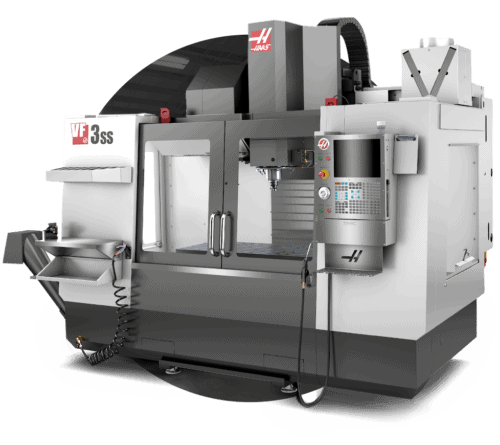

We also have one of the most technically capable machining floors in the United States — our plastic machining department uses state-of-the-art CNC machine tools. Our team excels at achieving tight tolerances, exceeding high customer expectations, and facilitating the creation of intricate designs.

Plastic Part Machining Capabilities

At Advanced Industrial, our commitment to quality starts from the plastics fabrication stage. Our unique, proprietary approach to design, machining, and supply helps us create complex parts used in numerous industries.

Our machining processes account for every variable, including workpiece orientation and workholding, feed rates, cutting speeds, and careful tool selection. Determining all relevant project parameters in advance of production allows our engineers and technicians to meet unique or challenging specifications. Our precision capabilities reduce the risk of chipping and enhance flexure, dimensional stability, heat tolerance, and more.

Accuracy and control are crucial when serving highly regulated industries where high-performance plastic parts must be suitable for use in extreme conditions. We serve numerous industries, including analytical instrumentation, food processing, life sciences, marine, material handling, and sample preparation.

We specialize in the following:

- Fabricating functional and aesthetically appealing parts

- Custom plastic bearings and wear components

- Plastic plates, rods, tubes, and sheets for future machining and finishing

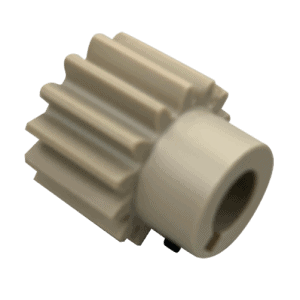

- Custom plastic spur gears

- Providing material application assistance

We adhere to stringent in-house quality management procedures. Inspections and testing ensure the pieces will meet design tolerance requirements and function as intended. We also conduct regular quality checks during the machining and finishing stages. Our in-house metrology equipment includes:

We adhere to stringent in-house quality management procedures. Inspections and testing ensure the pieces will meet design tolerance requirements and function as intended. We also conduct regular quality checks during the machining and finishing stages. Our in-house metrology equipment includes: