ACETAL(polyoxymethylene)

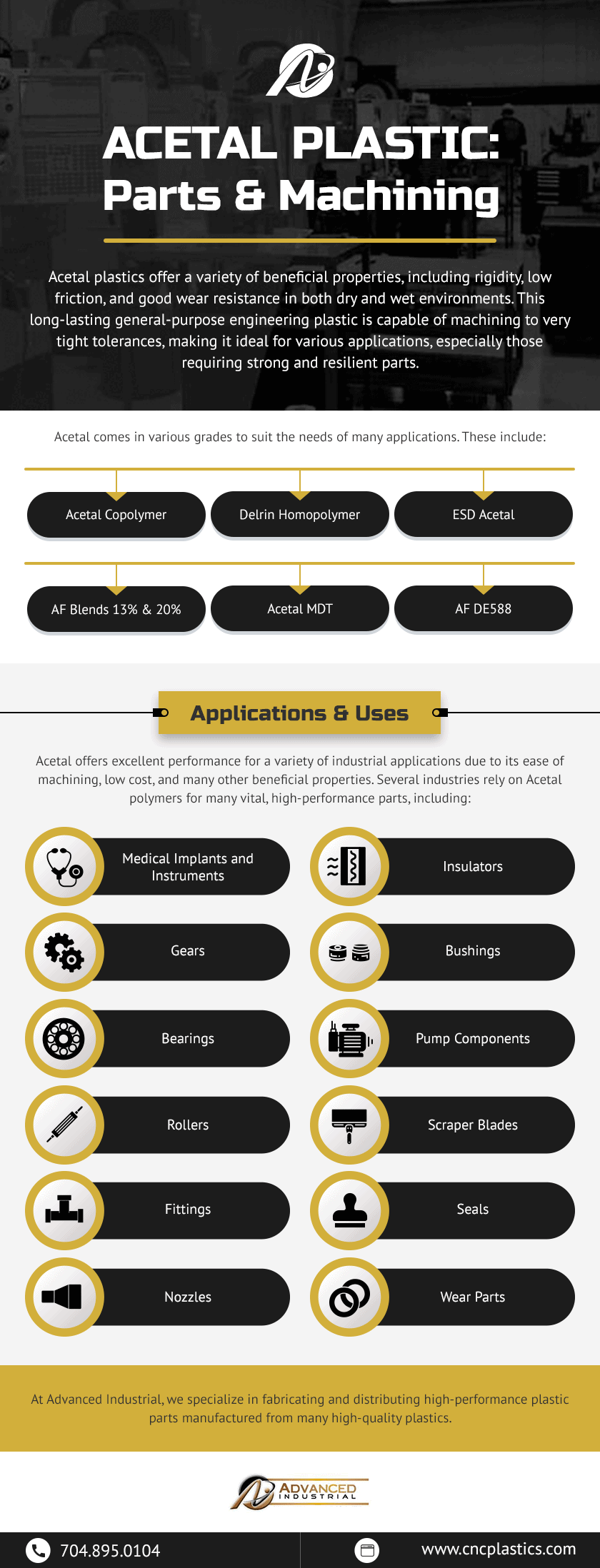

Acetal plastics offer a variety of beneficial properties, including rigidity, low friction, and good wear resistance in both dry and wet environments. This long-lasting general-purpose engineering plastic is capable of machining to very tight tolerances, making it ideal for various applications, especially those requiring strong and resilient parts. Several grades of acetal plastic are available, each of which offers its own unique properties to suit different needs.

Material Availability

- Extruded Sheet

- Compression Molded Sheet

- Extruded Rod

- Extruded Tubing (Tight Tolerance)

- Extruded Film

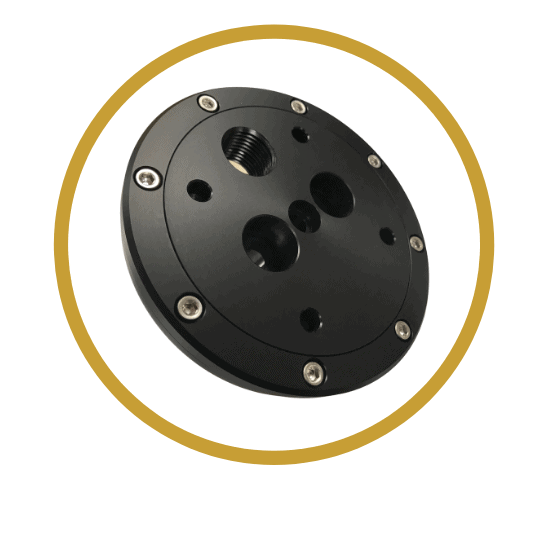

- Tight Tolerance CNC Machined Components

- Custom Gears

- Custom Bearings and Wear Components

Acetal is very easy to machine and makes an excellent choice for applications that require complex, tight tolerance machining. Acetal can replace Aluminum in many applications.

Acetal is available in White, Black and other FDA Compliant colors. Also available in metal detectable grade, Static Dissipative, PTFE impregnated and glass reinforced.

Materials available in the following shapes - contact us for more information:

Tubular Bar

Machined Parts

Rods

Sheets

Acetal Grades

Acetal comes in various grades to suit the needs of many applications. These include:

- Acetal Copolymer. This versatile, cost-effective plastic has many desirable qualities, including stiffness, strength, ease of machining, and good creep resistance and dimensional stability. It also has high tensile strength, low moisture absorption rates, and resistance to friction, solvents, abrasion, fatigue, and moisture, making it suitable for wear-prone parts and submerged or high moisture environments.

- Delrin Homopolymer. This specific type of Delrin is 20% glass-reinforced and offers great dimensional stability, excellent stiffness and strength, good machinability, and very high creep resistance. These features make it suitable for wear-prone parts in the automotive, construction, gear manufacturing, and fixture construction industries.

- ESD Acetal. This material offers non-sloughing and antistatic features, ease of machining, good wear properties, good mechanical properties, and chemical resistance. Common applications for this material include aircraft and aerospace technology, computer technology, mining equipment, conveyor technology, protection of electronics, explosion protection, and business machines.

- AF Blend 13% & AF Blend 20%. AF Blend 13 features 13% PTFE powder and good tribological properties with a limiting PV of 8,000 in dry running conditions. AF Blend 20 features 20% PTFE powder, excellent wear properties, high mechanical load capacity, low static friction, and good machinability. Common applications for these materials include packaging and paper machinery, automotive equipment, printing machines, and more.

- Acetal MDT. This FDA and USDA-compliant material is porosity-free and features good dimensional stability, rigidity, and hardness. Common applications include mechanical engineering, food processing equipment, and material handling equipment.

- AF DE588. This U.S. Navy Grade material features 20% PTFE fiber, good dimensional stability, excellent wear resistance, and very good sliding properties. These characteristics make it suitable for parts in the mechanical engineering, electrical, and material handling industries.

Our experts can help you determine the ideal grade to suit your industry specifications and application requirements.

Industries and Applications

Acetal offers excellent performance for a variety of industrial applications due to its ease of machining, low cost, and many other beneficial properties. Industries such as medical, aerospace, energy, and more rely on Acetal polymers for many vital, high-performance parts, including:

- Medical implants and instruments

- Insulators

- Gears

- Bushings

- Bearings

- Pump components

- Rollers

- Scraper blades

- Fittings

- Seals

- Nozzles

- Wear parts

Acetal Plastic Machining From Advanced Industrial

Acetal plastic offers a wide range of benefits and desirable qualities, making it ideal for various industries and applications. At Advanced Industrial, we specialize in fabricating and distributing high-performance plastic parts manufactured from many high-quality plastics. For more information about our capabilities, or to get started on your custom Acetal parts, contact our team of experts today.