Benefits of Peek Plastic Parts

PEEK Plastic Parts

There are many types and grades of polyetheretherketone (PEEK), some lending themselves to certain functions more readily than others. PEEK’s physical properties allow for broad usage across nearly every industry. Parts made from this highly machinable plastic can be found in bearings, piston parts, aerospace, medical prostheses, and many other products, with the range of applications expanding every day.

Advanced Industrial has served countless industries with our high-performance plastics, and PEEK continues to be our specialty on the market.

What is PEEK Plastic?

PEEK is a highly machinable, organic, semi-crystalline thermoplastic. Its polymer structure yields exceptional environmental resistances, dimensional stability, and mechanical strength. Some of the key performance characteristics of PEEK include:

- Suitability for use at temperatures persisting up to 250°C (483°F), and even higher in steam or high-pressure environments with maintained rigidity.

- Melting point of 343°C (649.4°F).

- Autoclavable for increased sanitation and medical applications.

- Extremely low toxicity and gas emission when exposed to open flames, increasing safety in high heat environments.

- Suitable for use in ultra-high vacuum pumps.

- Incredibly strong and stiff with excellent shatter resistance.

- Machinable with diamond-filmed, polycrystalline diamond (PCD), or polished carbide tooling (PCD cutters are recommended when machining glass-filled PEEK).

- High resistance to chemicals, solvents, hydrolysis, seawater, and many other aqueous environments.

- Dissolves very slowly in concentrated acid solutions, such as high molarity nitric and sulfuric acids.

- Creep-resistant, even at high temperatures.

- Can be filled with glass or carbon-fiber fillers for enhanced physical properties, such as greater ranges of thermal stability and improved mechanical strength.

- Little moisture absorption.

- Well-suited for hostile environments and makes an excellent candidate as a high-strength replacement of fluoropolymers.

- Durable, wear-resistant, and extremely long useful lifetimes, even in punishing environments and excessive wear applications.

- Resistant to high energy radiation.

- Inherently flame-retardant.

Benefits of PEEK Plastic

Thanks to the above characteristics, all grades of PEEK share the following benefits:

Types/Grades of PEEK Plastic

Advanced Industrial's PEEK plastics come in a variety of grades, including fiber-reinforced composite options:

PEEK Plastic Industries and Applications

Manufacturers and engineers are constantly finding new uses for PEEK. The material is highly versatile and able to be adapted for use in even the most extreme operating environments. Below are some examples of the current applications for PEEK.

Bearings, Bushings & Seals

PEEK offers high lubricity, low mating part wear, high load capacity, and easy machining make PEEK plastic perfect for high-wear bushings, bearings, and seals.

Pump & Valve Componenets

PEEK’s properties make it an excellent candidate for use in pump and valve components, including pump structural parts, valve seats, pump wear rings, and back-up rings.

Semiconductor Machinery Components

Semiconductor machinery components often utilize PEEK as a wafer carrier due to the extremely low levels of wear particles shed by PEEK compared to other carrier materials. PEEK polymers also have extremely low levels of ionic extractables, which act as doping agents.

Aerospace components

Aerospace components made from PEEK have a lower weight compared to many other materials with similar strength, which can reduce fuel costs, simplify production and assembly of components, and increase service life.

Medical Components

PEEK is autoclavable and extremely inert, which makes it ideal for medical components and equipment. It does not react with organic materials and is resistant to virtually all acidic/basic compounds. It has been used widely in orthopedics as the material for partial skull replacements due to its high strength and low interference with medical imaging studies.

Food Processing, Drying, & Dehydration

PEEK plastics are able to withstand the extremely high temperatures involved in food processing, drying, and dehydration without releasing toxic fumes or losing structural integrity. PEEK plastics are also well-suited to the high pressures employed during supercritical CO2 extraction, and as such are used widely to extract essential oils, food oils, and decaffeinated beverages like coffee.

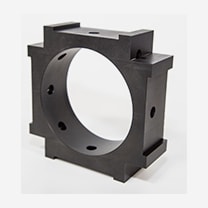

Protective Housings

Electrical components make use of PEEK plastics for protective housings that offer defense against high-energy radiation or aggressive chemical and thermal environments.

Wire & Cable Protection

PEEK is gaining traction as a material for wire and cable protection in demanding or high-temperature environments. PEEK forms excellent protection for wires used in situations with increased risk of fire due to its low flammability and low emissions when exposed to flame.

Structural Parts

Structural parts formed from PEEK plastics feature lighter weight and increased tensile strength.

Vacuum Belts

Vacuum belts used in chemical filtration are increasingly utilizing PEEK over other materials to achieve lower pressures without damage to the belt, facilitating longer service lives for the equipment.

We offer custom, high-performance PEEK bearings.

Advanced Industrial's High-Performance PEEK Plastics

Advanced Industrial is a distributor and fabricator specializing in CNC-machined components made from aluminum and high-performance plastics like PEEK. We are also the premier supplier in the nation of high-performance plastic machinable shapes, with stock materials that come in sheet, plate, rod, and tubular bar form. We present a healthy variety of bearing-grade PEEK composites with PV values as high as 120,000 while dry running, and we cut all materials to order with very tight tolerances.

For the best service in the industry, contact our experienced team today and tell us how we can help with your next project.