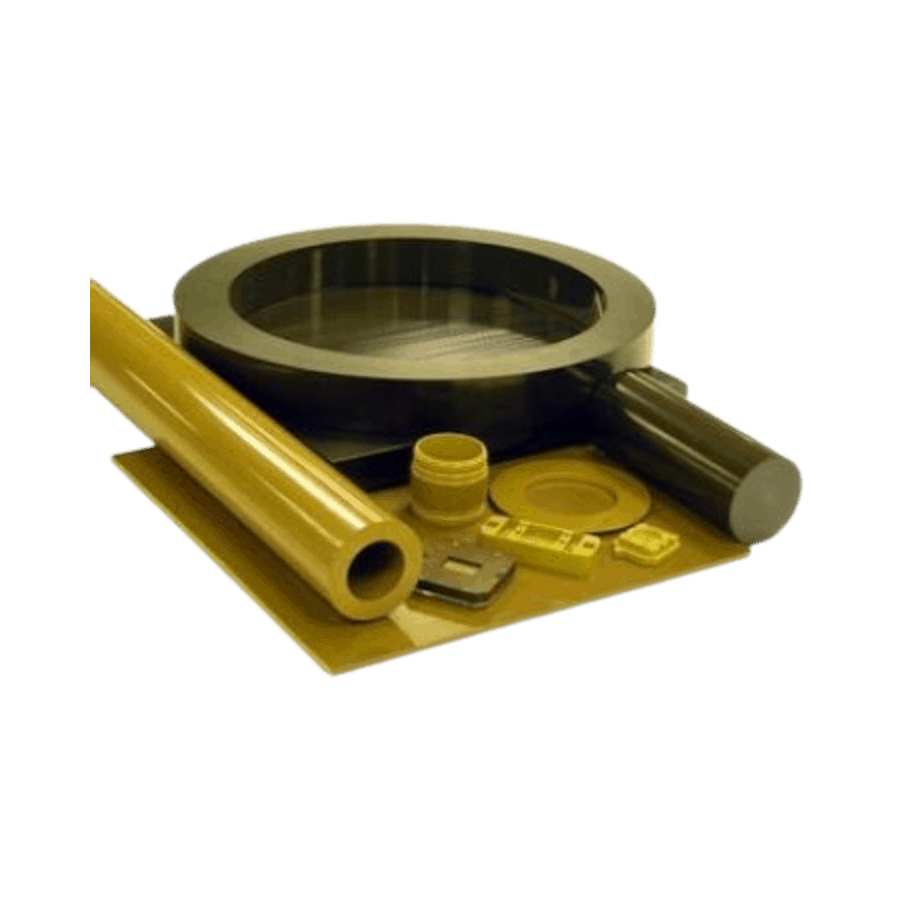

Torlon

Torlon is a high performance, melt processable plastic material. It’s ability to perform under severe stress combined with its resistance to elevated temperatures makes it ideal for various applications across many industries. At Advanced Industrial, we offer various grades of Torlon to suit the needs of your application.

What Is Torlon?

Torlon is a high-strength, versatile plastic used in a variety of applications. This material features superior creep resistance and mechanical strength over a wide range of temperatures and a very low coefficient of linear thermal expansion. It is an amorphous material with a glass transition temperature of 537°F. Torlon’s resistance to chemicals, high-energy radiation, hydrolysis, and UV combined with its ability to maintain physical properties under extreme temperatures make Torlon ideal for applications exposed to severe environments.

Torlon can be compression molded, injection molded, and extruded in many grades, including:

- Torlon 4203 is a structural/insulating grade that offers low thermal expansion, good insulating properties, and moderate coefficient of friction.

- Torlon 4301 offers a reduced coefficient of friction, excellent wear, very little stick slip, and flex modulus over 1 million psi.

Torlon 4630 is a special grade bearing material for improved performance in high-wear conditions.

Torlon 4630 is a special grade bearing material for improved performance in high-wear conditions.- Torlon 5030 is a high modulus polyamide-imide containing 30% glass fibers well suited for electrical insulators and thermal isolators.

- Torlon 7130 containing 30% carbon fiber is recognized as the strongest and stiffest of polyamide-imide grades. Torlon 7130 also has the lowest CLTE which closely matches both aluminum and many advanced composites. The high surface hardness resulting from the carbon fiber results in good wear resistance in well lubricated service.

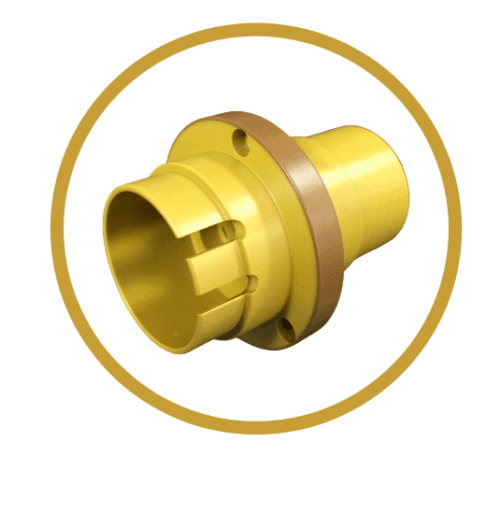

Parts machined from Torlon stock shapes are strong and durable, making it a preferred material for many industries and applications.