PTFE (Polytetrafluoroethylene)

Polytetrafluoroethylene (PTFE) has numerous applications. PTFE has a very wide continuous service temperature range. It performs at temperatures as high as 550°F and retains the majority of it’s mechanical properties at temperatures as low as (–268°F).

Material Availability

- Molded Rod

- Extruded Tubing

- Molded Tubing

- CNC Machined Components

- Sheet

- Molded Plate

- Skived Sheet

- Extruded Rod

- Custom Compounds in small batches

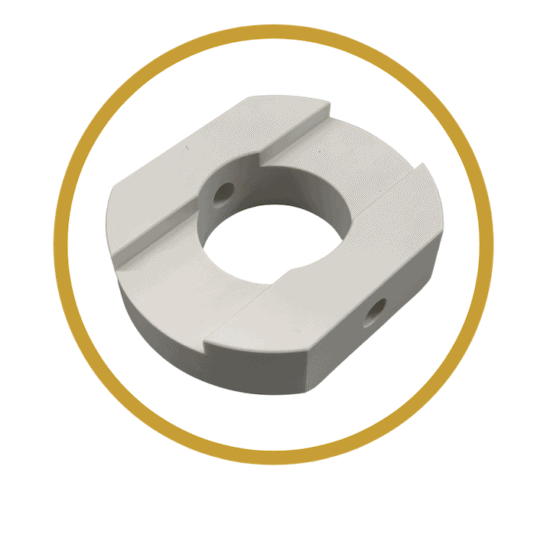

- Custom Bearings and Wear Components

- Tight Tolerance Machined Components

Often used in bearing and wear applications, PTFE has an incredibly low coefficient of friction (0.04) and when blended with glass, carbon or other polymers, PTFE can be a great choice for light duty self lubricating bearings.

PTFE is very easily compounded with other substrates. we offer many standard and custom formulations with relatively low minimums. Please call us for more information on compounds not listed below.