POLYIMIDES

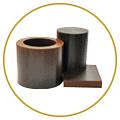

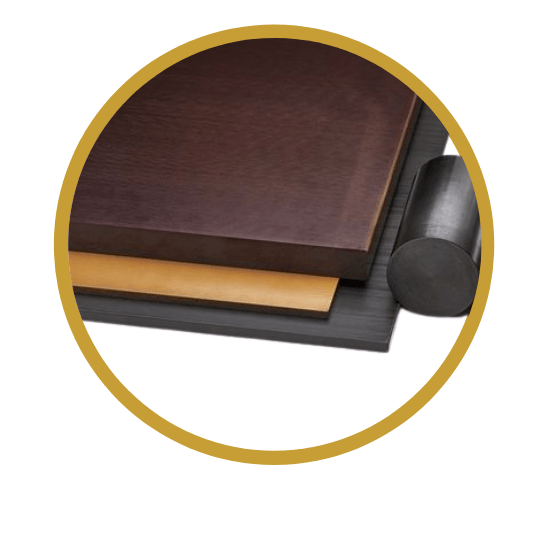

Polyimide PI material, is manufactured in standard stock shapes for machining and is produced in sheet, rod and tubular bar. Polyimide is a non melting high temperature polymer.

Material Availability

- Sheet

- Rod

- Tubular Bar

- Tight Tolerance Machined Components

- Custom Bearings and Wear Components

- Custom Gears

Polyimide exhibits high strength, dimensional stability, and creep resistance even at temperatures above 260°C. Low wear rates combined with the ability to work in unlubricated conditions and high PV-rates makes it the ideal material for challenging friction and wear applications, extending lifetime and reducing maintenance costs.

- High strength, modulus and stiffness also at high temperatures over 260 °C

- Excellent thermal and electrical insulation

- High purity, low outgassing in vacuum conditions

- Good machinability

- Inherently flame retardant

Materials available in the following shapes - contact us for more information:

Tubular Bar

Machined Parts

Rods

Sheets

Its high purity and low outgassing are needed for applications in the vacuum, space and semicon industry.

- Non melting high temperature polyimide

- Long term thermal stability 300°C (short term up to 400 °C)

- High heat resistance up to 470 °C (HDT/A)

- Good cryogenic properties down to -270 °C