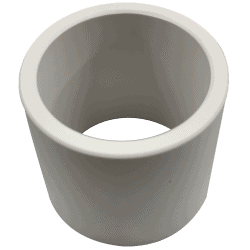

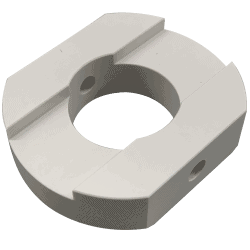

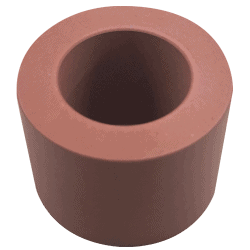

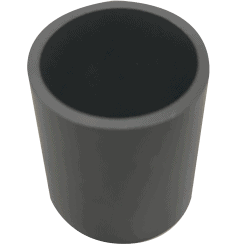

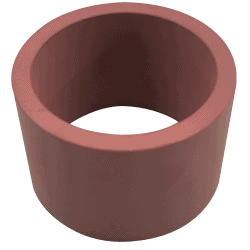

CUSTOM BEARINGS

Advanced Industrial can customize your bearing design experience by offering innovative solutions for your specific application. Our unique capabilities will allow you to design a bearing that fits your application, rather than having to design a device around a standard off the shelf bearing. We offer dozens of self-lubricating materials for light, medium and high-performance tribological applications that can run wet or dry and operate maintenance free.

BEARING GRADE MATERIALS

PEEK PTFE

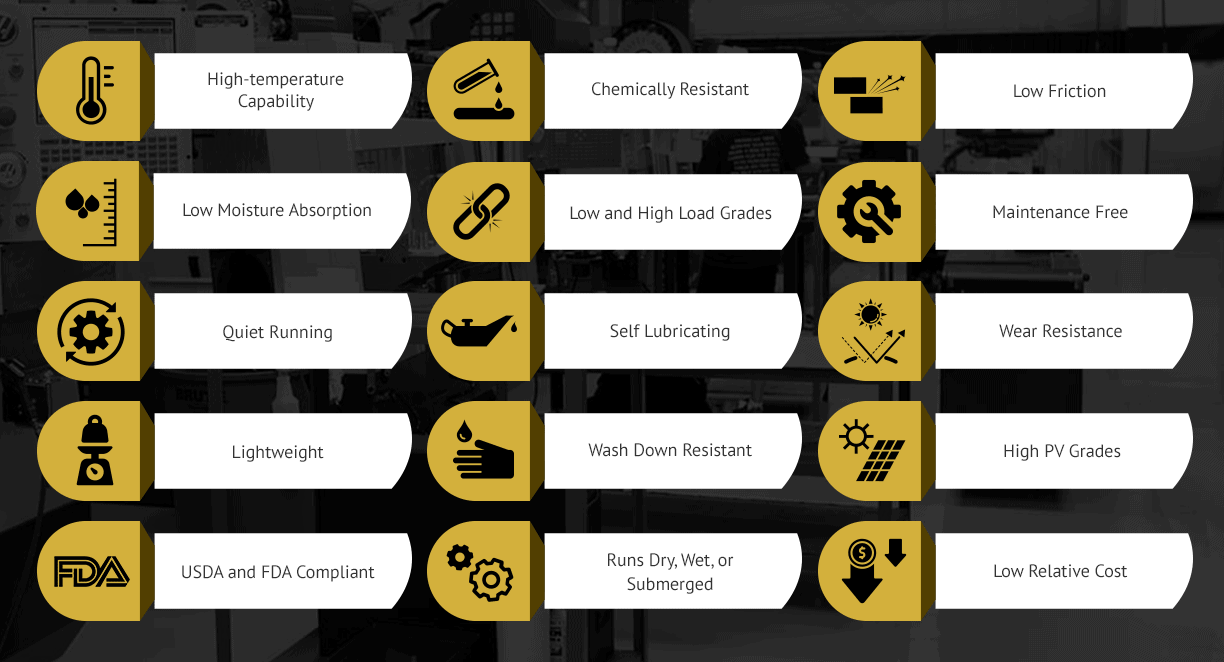

Teflon FilledBENEFITS OF PLAIN PLASTIC BEARINGS

Plastic bearings offer a wide range of benefits over stainless steel, bronze, or other traditional metal bearings, including:

- High-temperature capability. Plastic bushings can endure extreme temperatures for increased performance.

- Chemically resistant. Plastic’s ability to withstand harsh environments and chemicals without compromising performance makes it an ideal bearing material for applications where corrosion is a concern.

- Low friction. Plastic features a lower consistent coefficient of friction (COF), which leads to increased longevity of plastic bearings over metal.

- Low moisture absorption. The lower moisture absorption rate of plastic increases the stability of the end component.

- Low and high load grades. The versatility of plastic bearings makes them ideal for both low and high load applications.

- Maintenance free. Plastic bushings are resistant to dust, dirt, and chemicals, making them virtually a worry-free solution.

- Quiet running. Custom polymer bearings have a lower COF and ability to self lubricate, creating a low-noise design.

- Self lubricating. Plastic bearings are self-lubricating, eliminating the need for messy lubricants.

- Wear resistance. The high wear resistance of plastic means more cost savings for your company.

- Lightweight. Plastic allows for the final design of a component to be lighter.

- Wash down resistant. The integrity of plastic bearings are not phased with the use of salt water and other harsh substances.

- High PV grades. Polymers can withstand heavy loads and high speeds, making these types of bearings ideal for applications requiring high PV.

- USDA and FDA compliant. Custom plastic bearings have a high-sanitation rating to meet strict requirements and comply with industry regulations.

- Runs dry, wet, or submerged. Without the worry of rusting, plastic bearings can be used in a wide variety of applications that require wet conditions for longer service.

- Low relative cost. While plastic may have a higher upfront cost, its exceptional performance and low maintenance requirements make it the most cost-effective option for the long run.

These benefits allow plastic bearings to offer more design versatility and performance for a range of industries and applications.

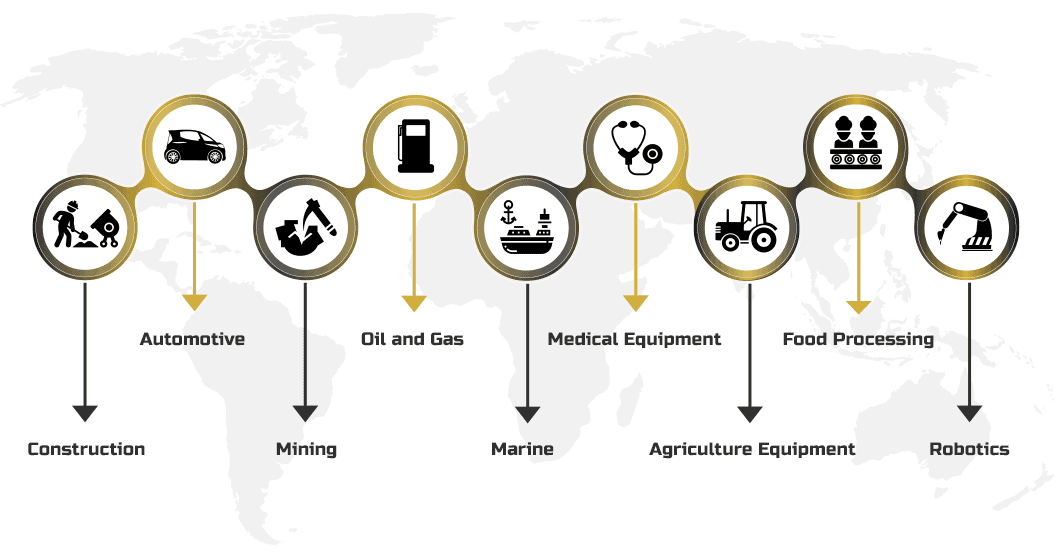

Plastic Bearing Applications/Industries

Plastic can tolerate a wide range of environments, making them suitable for many common applications. From conveyors to hydraulic presses and pumps, polymer bearings offer exceptional, long-lasting performance in virtually all mechanical products. Custom plastic bearings are found across the following industries:

- Construction

- Automotive

- Mining

- Oil and Gas

- Marine

- Medical Equipment

- Agriculture Equipment

- Food Processing

- Robotics

CALCULATE YOUR LIMITING PV

Calculating your Limiting PV is a great starting point when trying to determine which High Performance Plastic Material will work best in your Plain Bearing Application. Limiting PV is a calculation which uses the load on the bearing (pressure) and the shaft RPM (velocity) to give you a limiting PV value. Each of the High Performance Plastics below has it’s own limiting PV Value as calculated by the manufacturer of the material. If you need help using the Limiting PV Calculator or would like to discuss other variables or criteria regarding your specific application, please contact us at 1-800-265-7351 or email Paul at [email protected]

Innovative Solutions from Advanced Industrial

At Advanced Industrial, we offer innovative solutions that exceed customer expectations for all their plastic bearing needs. Our industry-leading technology and engineering capabilities allow us to create application-specific bearings for both low-volume and high-volume machined components. Along with our state-of-the-art and American-built equipment, we use only high-performance plastics for the development of advanced polymer bearings, granting them excellent longevity, even in the most demanding environments.

Self-lubricating plastic bearings offer many benefits over metal, making them the ideal solution for a wide range of applications. Whether you need 5 or 5,000 plastic bearings, the professionals at Advanced Industrial can help. Contact us today to learn more about our extensive capabilities for your custom bearing solutions.