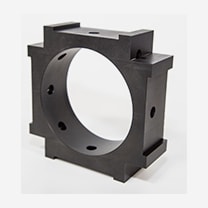

PEEK Machined Components / PEEK CNC Machining

PEEK (Polyether ether ketone) is a thermoplastic that has gained recognition in engineering and manufacturing due to its exceptional characteristics. It is ideal for producing machined components requiring strength, wear resistance, tight tolerances, durability and stability.

Advanced Industrial is a premier distributor and fabricator of high-performance PEEK machined plastic materials and products. We are equipped with state-of-the-art facilities and skilled technicians, allowing us to take on projects of any size and complexity. Whether you are looking at design prototypes or a large-scale production run, we are committed to delivering exceptional results on time and within budget.

PEEK: Material Properties for Uncompromised Performance

PEEK is a high-performance material that engineers across numerous industries rely on for its exceptional combination of properties.

- Superior Strength and Stability: PEEK offers outstanding mechanical and high impact strength, ensuring components can withstand demanding loads and maintain dimensional stability even in harsh environments.

- Thermal Endurance: PEEK excels in high-heat environments. With a continuous use temperature of up to 500°F (260°C), poly ether ketone is a reliable choice for applications exposed to extreme temperatures needing a high melting point.

- Chemical Resistance: PEEK exhibits exceptional resistance to a broad spectrum of chemicals, including harsh fluids and solvents. This makes it the perfect choice for aggressive environments like oil and gas.

- Biocompatible Potential: Medical grade PEEK is biocompatible, making an ideal solution for medical applications like implants and devices.

- Electrical Efficiency: PEEK boasts high dielectric strength and low dissipation factor. This combination makes it ideal for electrical components, ensuring efficient performance and minimal signal loss.

Ready to get started?

Material Availability

- Compression-molded rings/disks/rod/sheet

- Compression-molded tubing

- Custom bearings and wear components

- Custom compounds in small batches

- Custom gears

- Extruded film/rod/sheet

- Extruded tubing (tight tolerance)

- Injection molded tubing

- Tight tolerance CNC machined components

We are a supplier of PEEK in the following types and configurations:

Applications of PEEK Machined Components

PEEK's unique blend of properties translate into a wide range of applications across diverse industries:

Aerospace

Aerospace

The aerospace industry utilizes PEEK components because they offer an impressive mechanical strength-to-weight ratio and exceptional resistance to radiation and chemicals. They can also endure extreme temperatures. Bearings, seals, and structural parts are all examples of PEEK products utilized in aerospace.

Automotive

PEEK components are commonly used in the automotive industry due to their remarkable ability to resist heat, chemicals, and wear. Automotive applications of PEEK components include engine parts, fuel system parts, and electrical connectors.

Electronics

PEEK has a high dielectric strength, which means it can withstand high voltages without breaking down or losing its insulating properties. It also has a low dissipation factor for an efficient transfer of electrical energy without losing any power as heat. This makes it ideal for manufacturing electrical connectors, switches, and insulators.

Industrial

The plastic’s superior chemical resistance, stability at high temperatures, and excellent wear resistance make Peek parts a practical choice for industrial manufacturers. High-temperature resistance and excellent chemical resistance are hallmarks of PEEK plastic. As a result, it is frequently used in pumps, valves, seals, and other parts and products constantly exposed to aggressive chemicals or high temperatures.

Medical

Biocompatible medical-grade PEEK plastics play a vital role in the medical field. Due to their excellent strength, biocompatibility, and inherent resistance to wear, biocompatible PEEK grades are used in medical implants and devices.

Advanced Industrial: Your Partner for PEEK Machined Components

Advanced Industrial has extensive experience machining challenging parts from high-performance plastics, including machining PEEK. We offer a comprehensive suite of services designed to meet your specific project requirements and exceed your expectations.

- Machining Expertise: Our team possesses extensive experience machining challenging materials like PEEK. We leverage our expertise to ensure precise dimensions, exceptional surface finishes, and high-quality components that meet your most demanding specifications.

- Material Selection: We provide a comprehensive selection of PEEK grades to perfectly suit your application. Choose from virgin machined PEEK, glass-filled for enhanced strength, carbon-filled for superior wear resistance, or specialized bearing grades optimized for low friction.

- Commitment to Precision: We understand the importance of precision in critical applications. That’s why we utilize state-of-the-art CNC machining equipment to achieve tight tolerances and complex geometries, ensuring your PEEK components function flawlessly.

- Collaborative Partnership: Our team is dedicated to collaborating closely with you throughout the entire process. We take the time to understand your project requirements, recommend the most cost-effective and efficient solution in machining PEEK, and ensure you achieve optimal performance in your demanding applications.