Facilities

14 CNC Mills

(1) HAAS VF3SS High Speed Machining Center 30hp Vector Dual Drive, 12,000 RPM Spindle, High Speed Rapids, Renishaw Probe System, 24 position High Speed Tool Changer and High Intensity LED Lighting. 4th axis capable

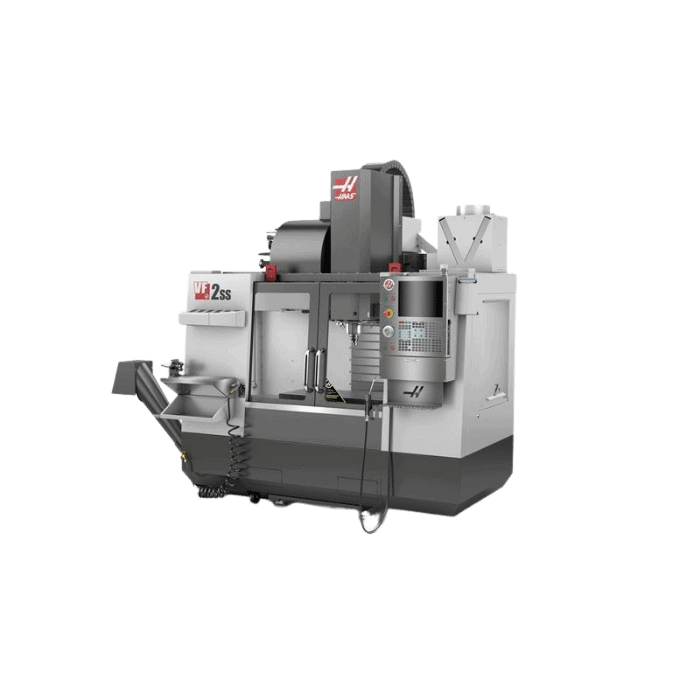

(6) HAAS VF2SS High Speed Machining Center 30hp Vector Dual Drive, 12,000 RPM Spindle, High Speed Rapids, Renishaw Probe System, 24 position High Speed Tool Changer and High Intensity LED Lighting. 4th axis capable.

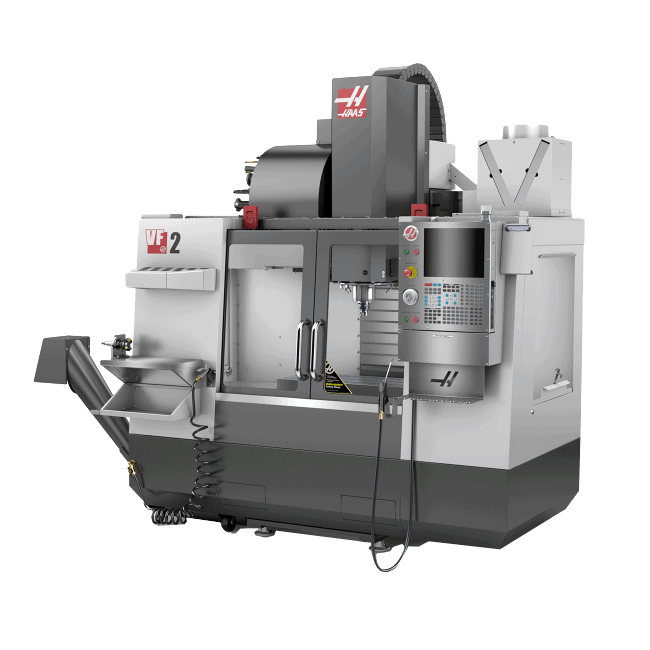

(1) HAAS VF2 Vertical Machining Center 30hp Vector Dual Drive, 10,000 RPM Spindle, High Speed Rapids, 24 position High Speed Tool Changer, High Pressure Flood Coolant system, High Intensity Lighting and Rigid Tapping.

(2) HAAS SMINIMILL2 High Speed Machining Center Specifically designed for high speed machining of small parts out of Plastics and Aluminum. 10,000 RPM Spindle, High Speed Rapids, and a 24 position High Speed Tool Changer. 4th axis capable.

(4) HAAS DM2 Mills The DM-2 is a compact, high-speed machining center built with proven Haas components and sub-assemblies. It is identical in construction and specifications to the DM-1, with the addition of 8″ of X-axis travel and table length. The machine’s shop-proven 40-taper inline spindle, 18+1 tool changer, high acceleration rates, fast rapids, and impressive short tool-change times make the DM-2 an attractive high-productivity machining center.

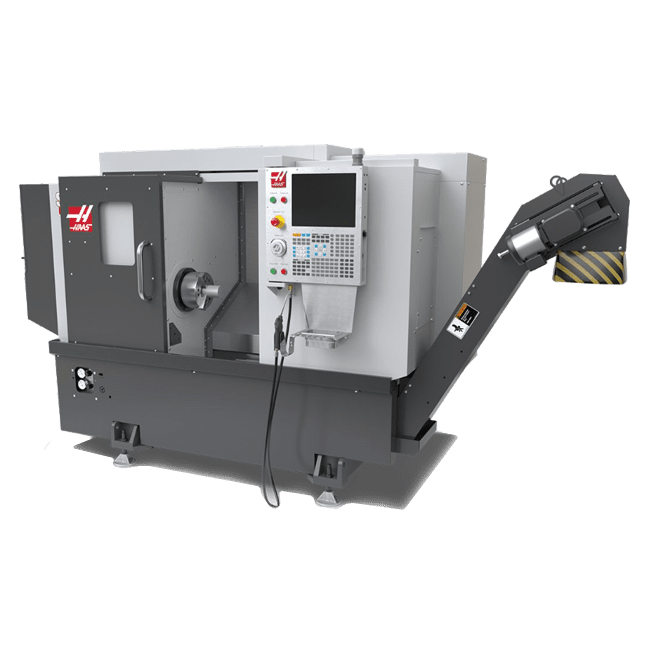

7 CNC Lathes

(1) HAAS ST10 High Performance Turning Center 6,000 RPM 1.75″ Diameter Through Spindle, 1,200 IPM Rapids, Automatic Tool Pre-setter, 12 Station BOT Turret, 14×14 Capacity and Tailstock with Hydraulic Quill.

(1) HAAS ST10 High Performance Turning Center 6,000 RPM 1.75” Dia Through Spindle, 1,200 IPM Rapids, Automatic Tool Pre-setter, 12 Station BOT Turret, 14×14 Capacity and High Pressure Coolant System.

(2) HAAS ST15 High Performance Turning Center 4,000 RPM 2.50” Through Spindle, 1,200 IPM Rapids, Automatic Tool Pre-setter, 12 Station Hybrid Turret, 14×16 Capacity, High Pressure Coolant System with Bar Feeder.

(1) HAAS ST35Y High Performance Turning Center 4,000 RPM 4.00” Big Bore Through Spindle, 1,200 IPM Rapids, Y Axis Milling, Drilling and Tapping, 12 Station BMT65 Turret, 18×23 Capacity, High Pressure Coolant System with Bar Feeder

Doosan Lynx 2100 Turning Centers Doosan’s Lynx series features high accuracy compact horizontal lathes. The machines produce superior surface finishes and offer multiple options to provide a customizable solution to many turning applications. Both Doosan Turning centers are equipped with 1,000 PSI Chip Blaster Coolant.

METROLOGY

(1) MITUTOYO CRT-PM443 Coordinate Measuring Machine

(1) Brown and Sharpe MicroVal 343 Coordinate Measuring Machine

(1) Deltronic DH216 Optical Comparator

(1) Vertex 410 Inspection System