PEEK Material – PEEK Machining

Polyetheretherketone (PEEK) is a high-performance polymer plastic that offers a range of beneficial properties that make it ideal for use in a variety of industries. It features outstanding wear resistance and mechanical strength along with resistance to harsh chemicals, high temperatures, and moisture. At Advanced Industrial, we are a distributor of various PEEK materials. We can provide PEEK in many forms, including rods, sheets, film, and more, to meet the needs of our customers.

Why Choose PEEK (Polyether Ether Ketone)?

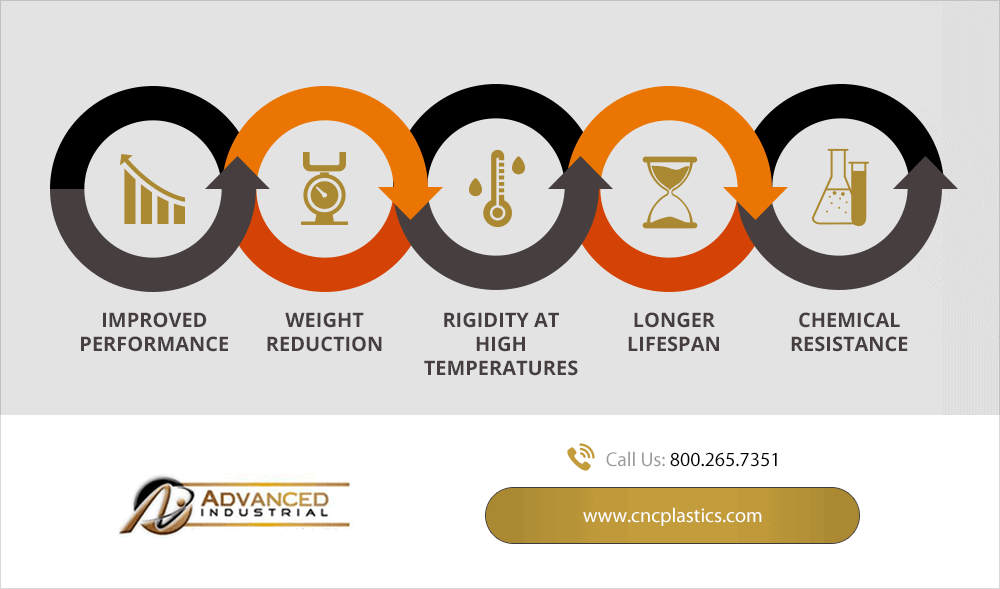

PEEK is one of the highest-performing thermoplastics available—combining extreme strength, thermal stability, and chemical resistance in a lightweight, machinable material. It retains its mechanical properties in high temperatures, aggressive chemicals, and demanding environments, making it ideal for aerospace, medical, semiconductor, and energy industries. If your part demands more than the average plastic can deliver, PEEK delivers.

What is PEEK plastic used for?

PEEK plastic is used in applications where conventional plastics fail—like high-temperature bearings, electrical insulators, spinal implants, and aerospace brackets. Its ability to withstand heat, friction, and chemicals makes it a preferred material in medical, aerospace, automotive, and semiconductor sectors.

What are the advantages of PEEK over other plastics?

PEEK offers superior heat resistance, tensile strength, and chemical durability compared to standard engineering plastics like nylon, PTFE, and ABS. These advantages make it ideal for mission-critical components that operate in extreme conditions.

Is PEEK plastic strong?

PEEK plastic is one of the strongest thermoplastics available, with tensile strength up to 17,000 psi. It retains its mechanical integrity under load and stress, even at elevated temperatures.

Can PEEK withstand heat?

PEEK withstands high temperatures, with a continuous use temperature up to 480°F (250°C) and a melting point around 343°C. It remains dimensionally stable and mechanically reliable in thermal environments that degrade other plastics.

Is PEEK chemical resistant?

PEEK is highly resistant to a broad range of chemicals, including acids, bases, solvents, and hydrocarbons. Its chemical inertness makes it ideal for use in corrosive or reactive environments.

How machinable is PEEK?

PEEK is an excellent material for CNC machining, offering tight tolerances and minimal thermal expansion during fabrication. It machines cleanly with proper tooling and is commonly used in precision parts manufacturing.

Is any grade of PEEK biocompatible?

Medical-grade PEEK is fully biocompatible and suitable for use in long-term implantable devices. It is inert, non-toxic, and widely approved for spinal, orthopedic, and dental applications.

Is PEEK plastic expensive?

PEEK is more expensive than standard plastics due to its advanced performance properties. However, its long service life and ability to replace metal in many applications often reduce total lifecycle costs.