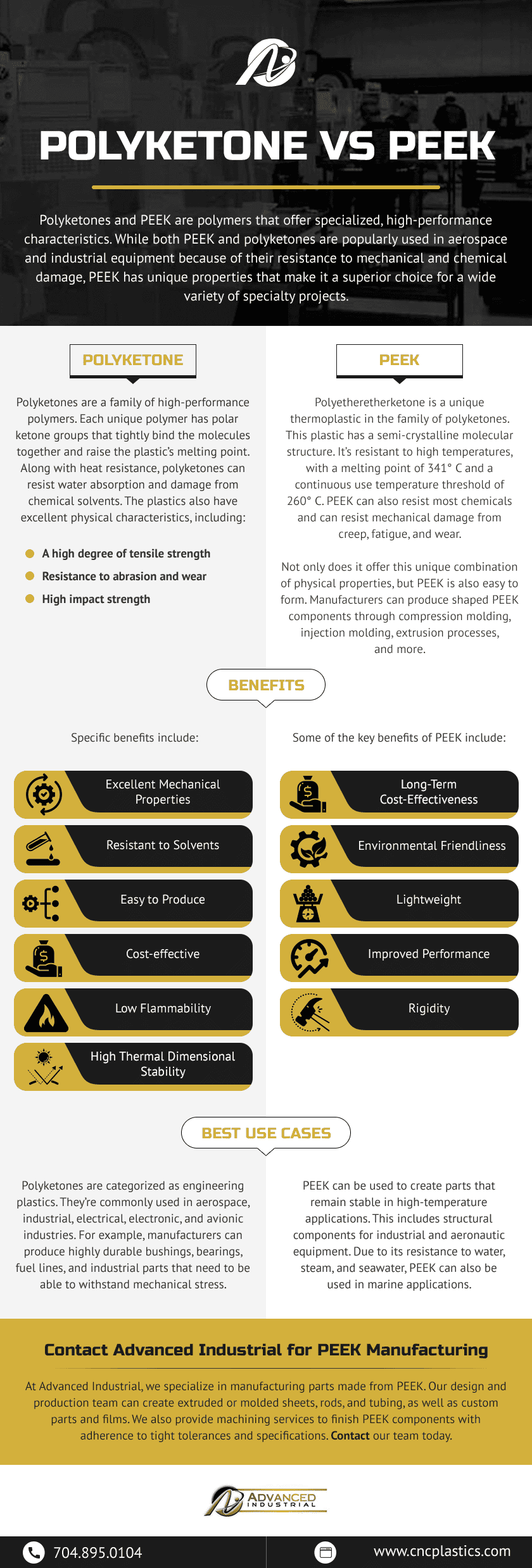

Polyketone vs PEEK

Polyketones and PEEK are polymers that offer specialized, high-performance characteristics. While both PEEK and polyketones are popularly used in aerospace and industrial equipment because of their resistance to mechanical and chemical damage, PEEK has unique properties that make it a superior choice for a wide variety of specialty projects.

Polyketone

Polyketones are a family of high-performance polymers. Each unique polymer has polar ketone groups that tightly bind the molecules together and raise the plastic’s melting point. Along with heat resistance, polyketones can resist water absorption and damage from chemical solvents. The plastics also have excellent physical characteristics, including:

- A high degree of tensile strength

- Resistance to abrasion and wear

- High impact strength

Benefits

The physical and chemical characteristics make polyketones stable for use across a wide variety of applications and environments. Specific benefits include

- Excellent mechanical properties

- Resistant to solvents

- Easy to produce

- Cost-effective

- Low flammability

- High thermal dimensional stability

Best Use Cases

Polyketones are categorized as engineering plastics. They’re commonly used in aerospace, industrial, electrical, electronic, and avionic industries. For example, manufacturers can produce highly durable bushings, bearings, fuel lines, and industrial parts that need to be able to withstand mechanical stress.

PEEK

Polyetheretherketone is a unique thermoplastic in the family of polyketones. This plastic has a semi-crystalline molecular structure. It’s resistant to high temperatures, with a melting point of 341° C and a continuous use temperature threshold of 260° C. PEEK can also resist most chemicals and can resist mechanical damage from creep, fatigue, and wear.

Not only does it offer this unique combination of physical properties, but PEEK is also easy to form. Manufacturers can produce shaped PEEK components through compression molding, injection molding, extrusion processes, and more.

Benefits

Some of the key benefits of PEEK include:

- Long-Term Cost-Effectiveness. While PEEK has a higher upfront cost than other polyketones, its long lifespan and resistance to damage make it an excellent choice for high-performance parts that must be able to withstand long-term use.

- Environmental Friendliness. PEEK is completely recyclable, making it a great material option for companies looking to boost their sustainability efforts.

- Lightweight. PEEK is relatively lightweight compared to its strength. This makes the material useful in a wide variety of contexts, such as aeronautics and aviation, where component weight plays an important role.

- Improved Performance. PEEK offers greater temperature resistance, chemical resistance, and resistance to physical damage than other polyketones.

- Rigidity. PEEK has a high working temperature threshold and an even higher melting temperature, meaning it will stay rigid and hold its shape even in high-heat applications.

Best Use Cases

PEEK can be used to create parts that remain stable in high-temperature applications. This includes structural components for industrial and aeronautic equipment. Due to its resistance to water, steam, and seawater, PEEK can also be used in marine applications.

Contact Advanced Industrial for PEEK Manufacturing

At Advanced Industrial, we specialize in manufacturing parts made from PEEK. Our design and production team can create extruded or molded sheets, rods, and tubing, as well as custom parts and films. We also provide machining services to finish PEEK components with adherence to tight tolerances and specifications. Contact our team today to learn more about our capabilities.